CNC System

In modern CNC systems, end-to-end component design is highly automated using computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The programs produce a computer file that is interpreted to extract the commands needed to operate a particular machine by use of a post processor, and then loaded into the CNC machines for production. Since any particular component might require the use of a number of different tools – drills, saws, etc. – modern machines often combine multiple tools into a single "cell". In other installations, a number of different machines are used with an external controller and human or robotic operators that move the component from machine to machine. In either case, the series of steps needed to produce any part is highly automated and produces a part that closely matches the original CAD design.

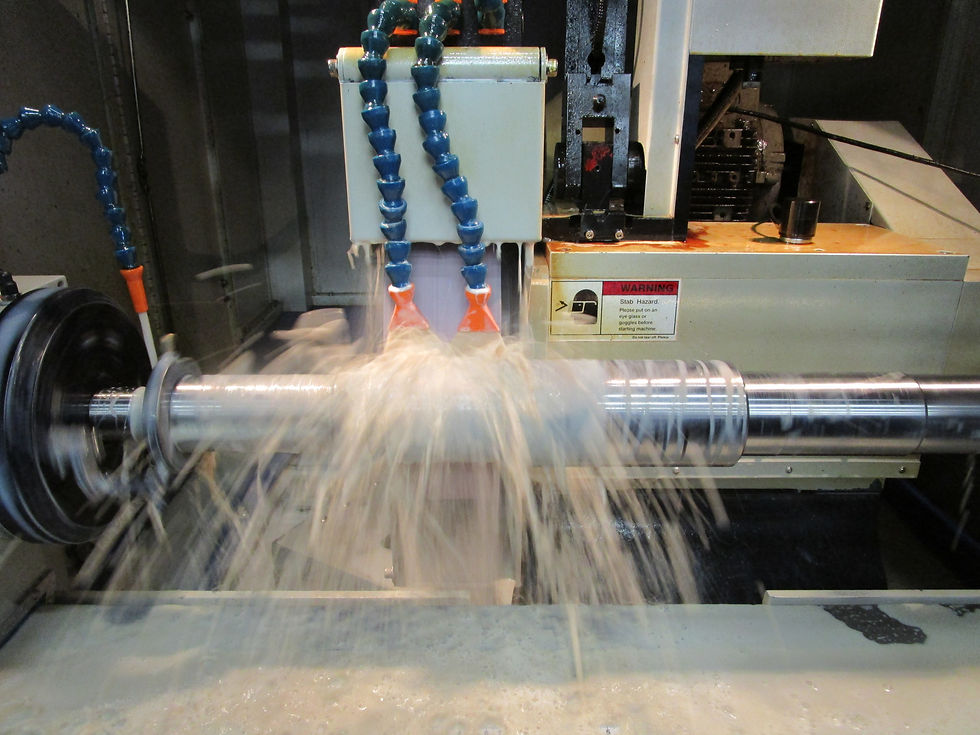

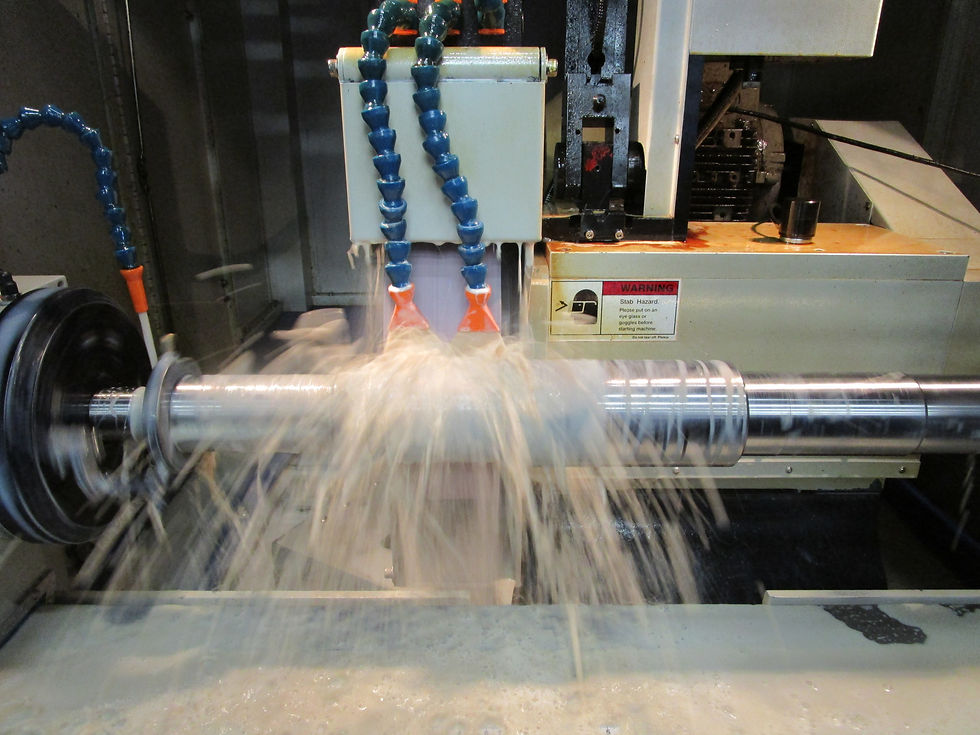

CNC Machine

CNC grinders are machines that grind workpieces while they are rotated. CNC grinders are able to make fast, precision grinds, generally using indexable grinding wheels. They are particularly effective for complicated programs designed to make parts that would be infeasible to make on manual grinders. CNC grinders have similar control specifications to CNC mills and can often read G-code as well as the manufacturer's proprietary programming language. CNC grinders generally have two axes (X and Z), but newer models have more axes, allowing for more advanced jobs to be machined.

Computer Numeric Control (CNC) is the automation of machine tools that are operated by precisely programmed commands encoded on a storage medium (computer command module, usually located on the device, as opposed to controlled manually by hand wheels or levers, or mechanically automated by cams alone.